How Simplified Engineering Improves Solar Construction Efficiency

October 02, 2025

In the world of utility-scale solar development, project timelines are directly tied to financial performance. Delays during the construction phase create immediate cost overruns and push back the crucial date of commercial operation. At Antaisolar, we address this pressure by integrating efficiency into the very design of our products. Our engineering principles focus on reducing complexity, which allows for a more predictable and accelerated build process. This examination details how a design-for-installation approach creates tangible advantages for project developers and EPC partners.

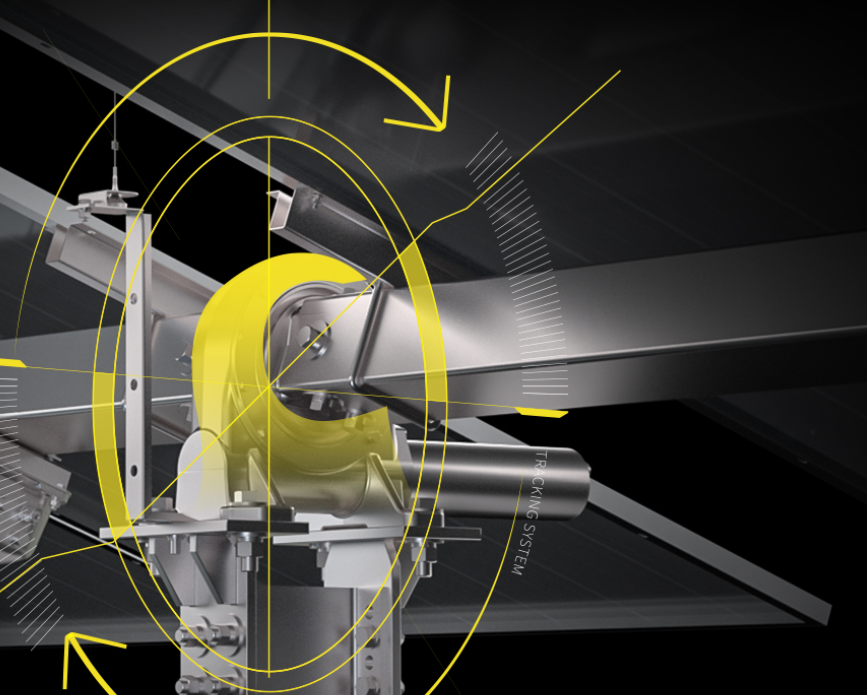

Reducing On-Site Complexity with Modular Pre-Assembly

A significant portion of construction delays originates from handling countless individual components and the high potential for logistical errors. Our strategy counters this through a fundamentally modular design. By incorporating up to 45% pre-assembled commercial components, we shift a substantial amount of the assembly work from the field to a controlled factory environment. This preparation means fewer shipments and a dramatic reduction in the time crews spend on inventory management and part organization on-site. The components for the solar tracker assembly are designed for intuitive connection, which minimizes the risk of mistakes and rework. This level of preparation ensures that once the site is ready, the physical construction of the tracking system can proceed without unnecessary delays, transforming a traditionally complex logistical operation into a streamlined and sequential build.

Enabling Rapid Deployment with Standardized Installation

The true value of a pre-assembled system is realized in the speed and simplicity of its installation. Our smart solar tracking system is deliberately engineered to require no specialized tools, enabling standard construction crews to perform the work efficiently. This eliminates dependencies on rare equipment or highly specific technician skills, which are common bottlenecks. Our human-centric engineering philosophy emphasizes logical, step-by-step installation processes. This reduces physical strain and the associated risk of workplace incidents, all while maintaining the structural integrity required for industrial-scale performance. The process becomes a straightforward, repeatable task that teams can execute with growing speed and confidence. This reliability is a defining feature of a modern smart solar tracking system, providing project managers with a predictable and efficient installation schedule.

We consider the ease of construction to be a critical performance metric for any solar technology. By designing our systems with a focus on modularity and simplified installation, we provide our clients with a tool to de-risk their project schedules and control labor costs. This practical approach to engineering ensures that our smart solar tracking solutions contribute to a smoother, faster, and more predictable path from project planning to energy generation, supporting the overall financial and operational goals of every development.

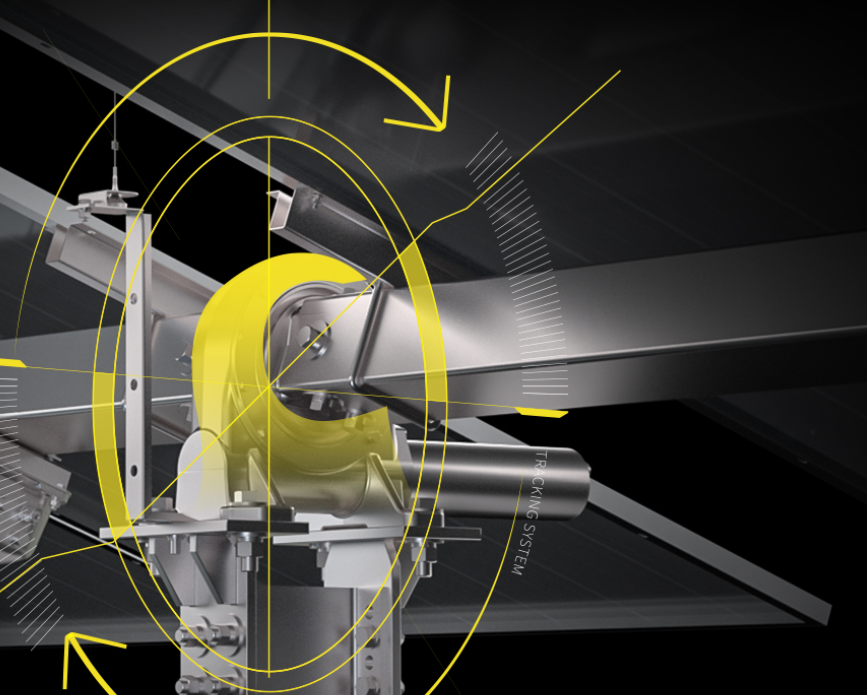

Reducing On-Site Complexity with Modular Pre-Assembly

A significant portion of construction delays originates from handling countless individual components and the high potential for logistical errors. Our strategy counters this through a fundamentally modular design. By incorporating up to 45% pre-assembled commercial components, we shift a substantial amount of the assembly work from the field to a controlled factory environment. This preparation means fewer shipments and a dramatic reduction in the time crews spend on inventory management and part organization on-site. The components for the solar tracker assembly are designed for intuitive connection, which minimizes the risk of mistakes and rework. This level of preparation ensures that once the site is ready, the physical construction of the tracking system can proceed without unnecessary delays, transforming a traditionally complex logistical operation into a streamlined and sequential build.

Enabling Rapid Deployment with Standardized Installation

The true value of a pre-assembled system is realized in the speed and simplicity of its installation. Our smart solar tracking system is deliberately engineered to require no specialized tools, enabling standard construction crews to perform the work efficiently. This eliminates dependencies on rare equipment or highly specific technician skills, which are common bottlenecks. Our human-centric engineering philosophy emphasizes logical, step-by-step installation processes. This reduces physical strain and the associated risk of workplace incidents, all while maintaining the structural integrity required for industrial-scale performance. The process becomes a straightforward, repeatable task that teams can execute with growing speed and confidence. This reliability is a defining feature of a modern smart solar tracking system, providing project managers with a predictable and efficient installation schedule.

We consider the ease of construction to be a critical performance metric for any solar technology. By designing our systems with a focus on modularity and simplified installation, we provide our clients with a tool to de-risk their project schedules and control labor costs. This practical approach to engineering ensures that our smart solar tracking solutions contribute to a smoother, faster, and more predictable path from project planning to energy generation, supporting the overall financial and operational goals of every development.

end